How to Perform Compound Bevels on Heavy Pipes

Actu Protem 03/16/2017Copying carriage option

Copying carriage option

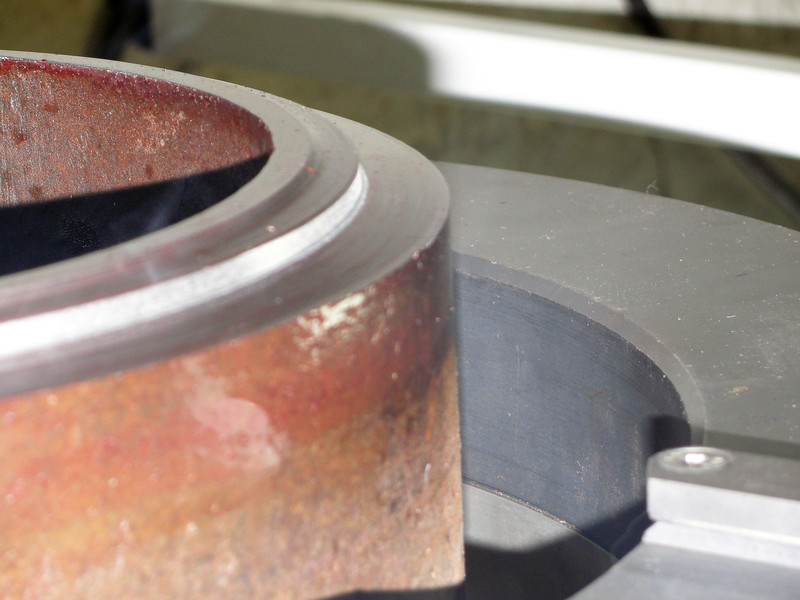

The copying carriage option was design to perform compound bevels for wall thicknesses over 50mm (1.968”).

The use of a compound bevel provides a reduction in the amount of weld metal that needs to be deposited in the weld bead. The aim is to avoid welding operations that are too long and too costly from a labor and consumables point of view.

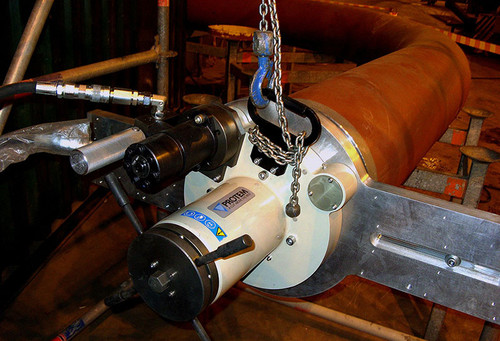

The Copying Carriage option is made for PROTEM beveling machines in the US40 to US450 range and PROTEM cutting and beveling machines in the TT-NG series.

Using HSS or carbide inserts allows machining on metal pipes including mild steel, chrome, stainless steel, duplex, super duplex, coppernickel alloy steel, inconel, P91, aluminium, copper, exotic alloys and more.

To implement the copying carriage system, simply remove the tool plate from the unit and fit the copying arm on the machine. This implementation is fast and easy to do. Once it has been completely equipped with its copying arm, the machine is ready to perform beveling operations

During the machining operation, the operator’s safety is ensured by the safety cover which is situated over the copying arm during rotation.

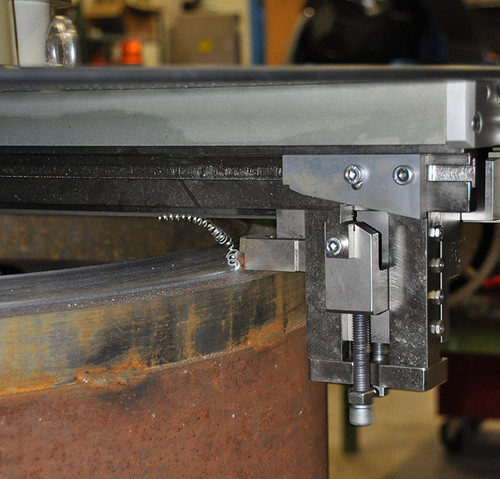

Reliable and accurate, the copying carriage system performs machining operations by using a copying cam. The copying cam is connected to the tool holder by a ‘’follower finger’’ which provides radial movement to the carriage.

In order to guarantee that the land or root face has a constant width over the whole circumference of the pipe, a counterboring tool may be added on the copying carriage.