PROTEM – A CUT ABOVE THE REST

"Before anything else, preparation is the key to success."

Alexander Graham Bell

The PROTEM Group: a leader in the manufacture of high quality welding preparation machines

The PROTEM Group is composed of two autonomous entities and a highly complementary brand which enables it to offer a wide range of machine-tools and services for all machining and welding preparation work for tubular components, boiler and heat exchanger tubes, for the replacement of steam generators, for the machining of flanges and valves, for the dismantling of the internals of nuclear reactors and nuclear vessels.

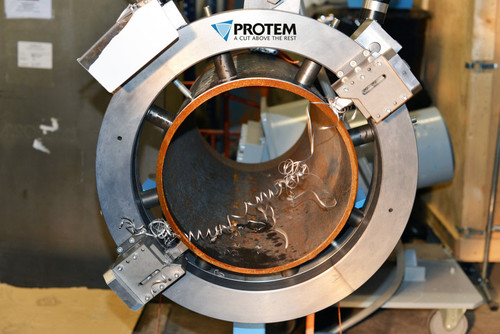

The first entity, PROTEM, is a company which specializes in the study, conception and manufacturing of portable machines for construction, maintenance, repair, and dismantling of tubes and pipes. PROTEM machining applications are varied from orbital cutting, severing, beveling, squaring, counterboring, facing, surfacing, drilling and boring to cutting heat exchanger tubes to various lengths, removal of weld joints, replacement of steam generators, etc.

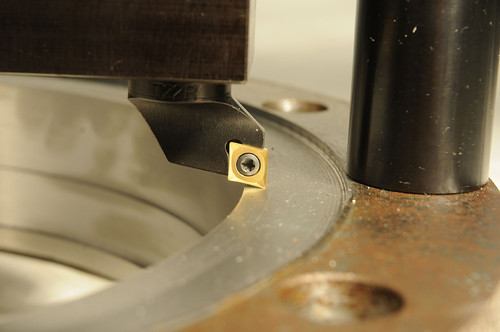

The second entity, SERCO, is also a company which specializes in the study, conception and manufacturing of mobile machining units. SERCO’s distinction comes from its capacity to design and manufacture equipment whose components enable the machine operator to obtain a perfect rigidity when the machine is fixed onto flanges and valves. This allows very high precision machining, up to an accuracy of 0.001 mm. SERCO is widely regarded as the only worldwide manufacturer to offer machines with an independent adjustment of concentricity and flatness. Moreover, the SERCO mobile machining units are specially designed to be used in tight spaces and demanding environments.

The PROTEM Group created the ULTIMASTER brand in order to offer a complete range of orbital cutting and tube squaring machines dedicated to tubes with thin wall thickness.

Thanks to its powerful technical and human resources, the PROTEM Group is able to manufacture portable and transportable machines and also machines which are specially designed to meet the requirements of customers from many fields of activity such as Energy (Nuclear, Oil & Gas, Boiler, Renewable Energy), Tube and Valve manufacturing, Welding, Shipbuilding, Chemistry, Aerospace and Aircraft industries and High Purity industries (Pharmacy, Semiconductors, Food, White Rooms…).

For more than 50 years, the PROTEM Group has demonstrated its flexibility, responsiveness and capability to adapt itself to complex situations which has established the PROTEM Group worldwide as the leading manufacturer whose entities have taken part in major industrial projects:

- More than 20.000 PROTEM and SERCO portable machines are being used all around the world.

- PROTEM and SERCO have designed more than 3500 specialty machines.

Innovation, highest quality and reliability are constant goals for the PROTEM Group which enables it to anticipate the needs and expectations of customers and partners.

Thanks to its success and the confidence shown by customers worldwide, the PROTEM Group is proud of its position as a global leader in the portable machine tools market.

Beveling Machines

- OD and ID mount.

- Machining diameters from 8 mm (.315″) to 5000 mm (196.85″).

- Machining wall thicknesses : 0.5 mm (.020″) to over 100 mm (3.934″).

- For all types of metals, alloys and steel.

Orbital cutting and beveling machines

- OD clamping for diameters ranging from 0.5″ to 168″

- Machining wall thicknesses: 0.5 mm (.020″) to over 100 mm (3.937″).

Flange and valve facing machines

- OD or ID mount.

- Machining diameters from 25 mm (.984″) to 5000 mm (197″) (larger diameters are available upon request).

- Machining wall thicknesses : 2 to 350 mm (.079″ to 13.779″) and over.

Specialty Machines:

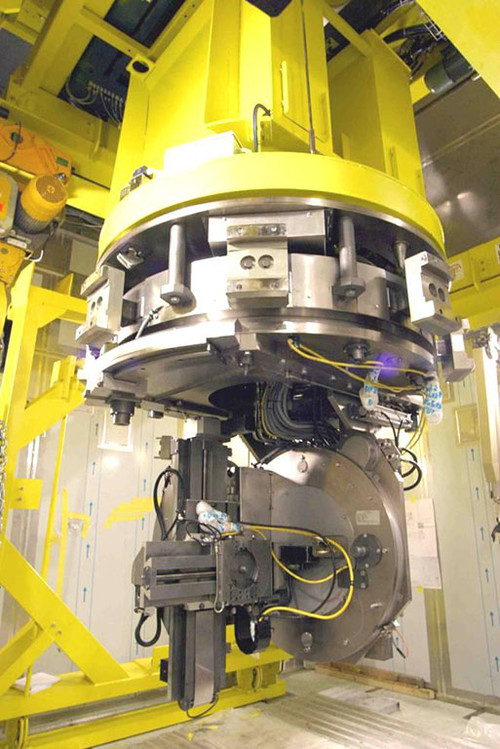

Nuclear Equipment:

PROTEM designs equipment for the construction, maintenance and dismantling of nuclear installations and components.

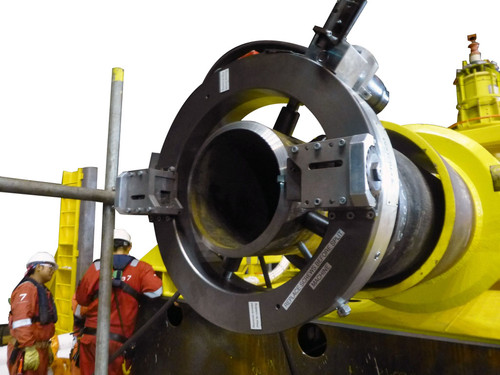

Oil & gas industry

PROTEM offers a complete range of equipment dedicated to applications in the oil & gas industry.

For applications onshore, offshore, on spoolbases, under water and under the most severe conditions.

These machines perform welding preparations by high speed cutting, beveling and/or counterboring operations on tubes and pipes with diameters up to 168″.

Français

Français  Deutsch

Deutsch  Español

Español  Pусский

Pусский  中国

中国  Polski

Polski