Ten Tips to Improve Productivity in Your Machining Operations

Newsletters 06/14/2017You can easily improve your productivity if you have a reliable machine.

You can easily improve your productivity if you have a reliable machine.

You can easily improve your productivity if you have a reliable machine. What is worse than a monthly break down of a machine? Having to stop production to send the machine in for repair, which results in a large loss in production time.

The selection of a reputable manufacturer is necessary to avoid this inconvenience. In a niche market, expertise and experience is a guarantee of quality.

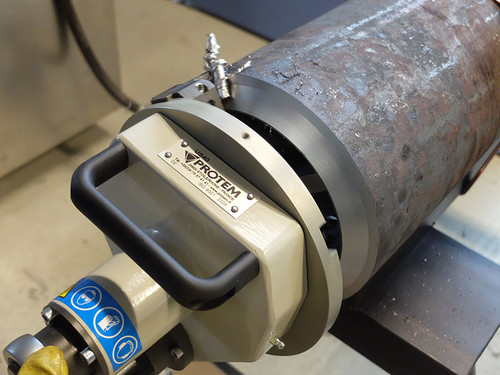

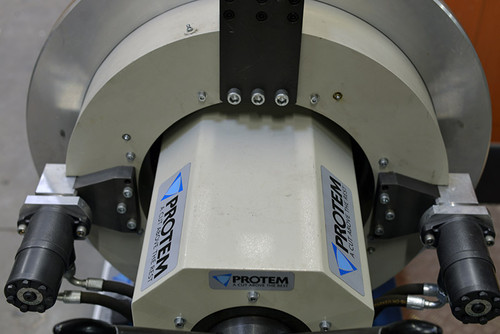

PROTEM designs and manufactures equipment used for the construction, maintenance and dismantling of tubular components. Our machines are designed, manufactured and assembled in our premises in France and Germany, ensuring perfect control of the process and the ultimate quality of our equipment.

Whatever your needs, PROTEM (PROfessionalism, Technical know-how, and Expertise) will help you make the right choice for the proper machining equipment.

In meetings and discussions, we will ask for the diameter range of your tubes. We will also define your needs in order to have the exact technical specifications you require to achieve the necessary results for your machining operations. Your production volume and your machining specifications will enable us to select the right machine that will meet your expectations.

Machining time optimization consists of choosing the right equipment and tools to ensure reliability in the machining process while maintaining the highest productivity.

What is your desired production volume? Assembling pipes by butt-welding is a finishing operation which comes at the end of the tube manufacturing process. The performance of the machining equipment will have a direct bearing on manufacturing time.

An analysis of machining performance is necessary to choose effective machining equipment. You must take into account the cutting head gear drive and the feed stroke. With these two parameters and the tube material, you will be able to calculate the machining time as well as the total tube manufacturing time.

The technical features of PROTEM machines are available on request. We invite you to contact us through our website to receive the technical data you require.

From the initial set-up to the end of the machining process, you need the proper equipment so that it is as fast as it is efficient.

The technical features you should verify are:

The portability of the machine: PROTEM has some of the lightest weight machines on the market. They can be set up easily. Because of their light weight, they can be used by a single operator.

The Clamping System: Machining performed with the right clamping system will have significant impact on the execution speed and the machining quality. To learn more about different clamping systems, we invite you to consult the article, Tube Clamping During Machining Operations. |

Automatic Feed: Weld joint extraction and beveling operations on heat exchangers takes a lot of time and requires the right technology. The US-TP series are fully automated beveling machines. The clamping and the feed are automatic and adjustable. The automatic feed offers a significant time reduction. With this technology, you will drastically increase your productivity.

An electric drive that gets hot after two bevels! Your machine probably doesn’t have the right motor. What is the best drive in this case?

PROTEM proposes three different types of motors to best meet your needs; pneumatic, hydraulic or electric. The budgetary constraints, the availability of a compressor, on-site machining, the compact design for tight spaces; all these factors will determine your choice of motor.

The power of these motors varies. For example, for heavy-walled tubes, a double hydraulic or pneumatic drive should be considered. To be able to do perfect and efficient machining, the motor is fundamental to maximizing your production. |

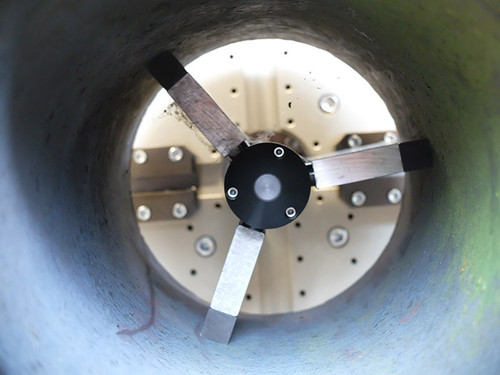

When we look at the market most beveling machines have a tool holder with two or three tools on it.

In the standard version, the tool holder on the PROTEM beveling machine can accomodate four tools.

Machining operations, such as facing, beveling and counterboring can be carried out simultaneously. Two or more tool bits used simultaneously ensure a perfect balance of forces during the machining operation.

Other machining operations can be done, such as, performing compound bevels on heavy pipes, removal of weld joints on tube sheets and/or cutting tubes to length on tube sheets.

Saving time will be important, particularly for applications that machine thousands of tubes, like heat exchangers, for example.

PROTEM offers a large range of cutting tools that make a variety of angles and specific shapes (I, V, J, X, compound bevels, counterboring, etc.). Carbide or HSS tool bits ensure a perfect welding preparation.

Carbide tools are naturally harder than the HSS tool bits with cutting speeds that are four times higher. These carbide tools are used with tubes made of hard steel at higher cutting speeds.

Also, the coating used on tool bits is a standard practice used in machining operations, such as, high speed machining. The coating improves the tool’s performance and can resist high temperatures that are a result of high machining speeds.

PROTEM offers TiN Coating (titanium nitride) that is specifically made to reduce operational costs because of its greater wear resistance. The TicN Coating (titanium carbonitride) is an extremely hard ceramic material that is specially recommended for materials that are particularly difficult to machine.

Multi-function, versatile machines are in high demand because of their ability to perform many machining operations on various components (tubes, elbows, plates, valves) by using a single machine.

The reduction in investment costs for this kind of machine is about a minimum of 30%. The purchaser invests in one machine instead of three. Additionally, there is a reduction in training costs, as the operator will only have to train on one machine.

For example, PROTEM beveling machines (US series) can machine tubes and re-surface flanges by utilizing the flange facing attachment option. For larger diameters, we offer a special kit that increases machining capacity. For heavy-walled pipes, buying a new machine will not be necessary, the copying carriage option is designed to perform compound bevels for wall thicknesses over 50mm (1.968”). |

PROTEM also offers high speed beveling machines (CTA or BB series). They are available with options, such as, an automatic clamping system, tube conveyors, tube storage table and chips conveyors. Any or all of these options will drastically increase your productivity.

The versatility of a machine is very important to any project. Anticipating your future needs will help you to save time and money.

While the use of a PROTEM machine that is durable, light weight, and portable, makes a huge difference in productivity, operators should also be fully trained and understand machining basics, such as, how to achieve a perfect weld.

A good understanding means properly knowing the importance of tube preparation before welding. Also, what are the things that should be controlled prior to machining for safety reasons. With its many years of experience and all its expertise PROTEM has developed training programs designed to familiarize users, during maintenance operations, with the procedures to be implemented when installing and setting up our equipment. This knowledge will improve your productivity and reduce your costs by reducing the reject rate and re-machining costs. |

Over time, your needs change and technology evolves. PROTEM will continuously offer new functionality on the equipment you already have.

Our team will select the parts and upgrades for your machine. This is the key to lasting machine success in optimum conditions.

We offer maintenance contracts or machine upgrades which consists of upgrading the essential components to give added life to your machine.

These services are essential to protect your investment over the long-term and will improve your productivity with machines that provide superior safety and state of the art technology.

--------------------------------------------------------------------------------------------------------------------------------------

In addition to these ten tips to improve productivity in your machining operations, a summary of the key elements so consider in choosing the right equipment is shown below

The manufacturer:

| The machine:

|

Tools and options:

| Services:

|